1. What Is Folding Carton Packaging?

Lightweight and adaptable, folding carton packaging finds extensive use within the retail packaging realm as well as e - commerce. Predominantly crafted from cardboard - type packaging like paperboard or thin cardboard, its design allows for flat - folding, beneficial for storage and assembly as required, offering cost - efficiency to businesses with restricted warehouse room.

Folding cartons, unlike bulkier choices, shine in product display: high - quality graphics can be printed on them through digital print techniques or offset print methods, rendering them perfect for industries emphasizing branding, such as cosmetics, food, and electronics. Take a skincare brand, for instance. It may utilize a folding carton with a matte finish and customized logo to boost its product's shelf attractiveness.

2. Pros and Cons of Folding Cartons

Key Advantages of Folding Cartons

- Cost - Efficiency in Branded RetailFor small - to - medium production runs, folding cartons, unlike rigid boxes with thicker materials, offer 30 - 40% cost savings. Ideal for startups or businesses focused oncustom packagingwith low upfront expenses.

- Space-Saving Storage: Flat-folded design reduces warehouse storage needs by up to 70% compared to pre-assembled corrugated or rigid boxes—critical for e-commerce sellers with limited space.

- Printing & Branding: Multifaceted: Employs sophisticated methods such as UV Printing(for lustrous, abrasion - resistant finishes) and embossing, making products prominent in retail - oriented packaging In contrast to basic corrugated boxes, folding cartons can comprehensively mirror your brand identity.

Limitations (vs. Other Packaging Types)

- Limited Load - Bearing Capability: Unsuitable for weighty items like large appliances. For transporting heavy goods, corrugated boxes ensure superior protection. Conversely, folding cartons prove optimal for lightweight products, those weighing under 5 lbs.

- Lower Durability Compared to Rigid Boxes: Luxury items like watches and high - end gifts benefit from rigid boxes due to their thick, dent - resistant materials such as chipboard. Mishandled folding cartons in transit? They might crease.

3. What Are Corrugated Boxes, and How Do They Work?

Boxes that are corrugated play the role of mainstays in packaging for e - commerce as well as shipping. Comprising three layers, there are two outer flat liners crafted from kraft paper and an inner wavy layer known as “fluting” which cushions. Their structure endows them with far greater durability compared to folding cartons, particularly in safeguarding products during long - distance transportation.

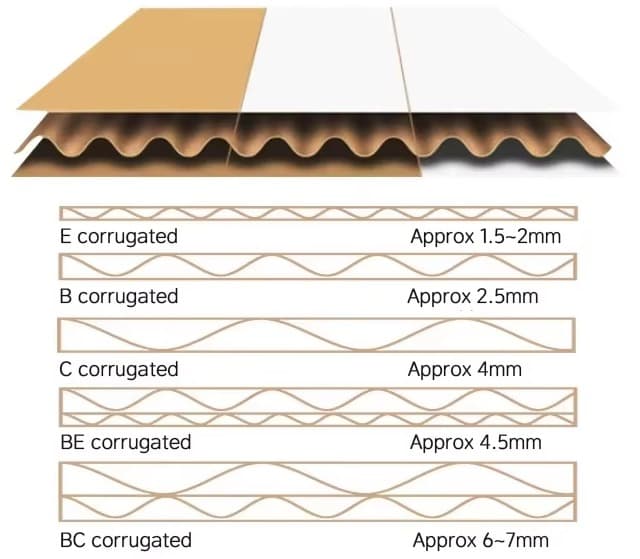

Utilized prevalently for massive - scale printing and transportation, corrugated boxes present diverse flute dimensions (such as B - flute for moderate strength, E - flute for light - duty safeguarding). These boxes are essential in sectors like logistics, manufacturing, and food delivery—areas where product damage prevention is imperative.

4. Pros and Cons of Corrugated Boxes

Key Advantages of Corrugated Boxes

- Exceptional Shock Resistance: During shipping, the fluted layer soaks up shocks, slashing product damage by a max of 60% relative to folding cartons. Hence their status as prime pick fore - commerce packaging(like furniture, electronics shipping).

- Eco-Friendly & Recyclable: Most corrugated boxes are made from recycled materials and are 100% recyclable—appealing to consumers and brands focused on sustainability (a major trend in 2025packaging).

- Bulk Shipping Cost - EfficiencyCorrugated boxes, for large quantities (1,000+ units), have lower per - unit costs compared to rigid boxes. And they're well - matched withbulk - scale printingfor straightforward branding like company logos on shipping boxes.

Limitations (vs. Other Packaging Types)

- Constrained Branding Elasticity: Basic designs can be imprinted on them through flexographic printing, but corrugated boxes lack folding or rigid boxes' smooth surface, weakening high - end graphics like metallic finishes. For luxury retail, rigid boxes outperform.

- Bulkier Than Folding Cartons: Even when flat, corrugated boxes take up more space than folding cartons. This can increase storage and shipping costs for businesses with small order volumes.

5. What Defines Rigid Boxes, and When to Use Them?

Premium pre - assembled rigid boxes, or “setup boxes,” crafted from thick, inflexible materials like chipboard or paperboard with a foam core. Differentiating from folding cartons, their permanent shape - retention suits luxury and high - value items, as they don't fold flat.

Incorporated commonly are packaging for cosmetics (take perfume boxes as an instance), sets for gifts (like jewelry, fine chocolates), and electronics of premium grade (such as high - end headphones). The conveyance of quality through their robust build and refined finish endows them with potency in brand positioning.

6. Pros and Cons of Rigid Boxes

Key Advantages of Rigid Boxes

- Luxury Brand AppealRigid boxes? Their thick, structured design and knack for premium finishes like velvet liners or gold foil stamping? Ideal for high - end products. In forging a 'premium unboxing experience', they trounce folding and corrugated boxes, a linchpin of customer loyalty.

- Exceptional Durability: Rigid boxes resist dents, tears, and creases better than folding cartons. They also offer more protection than corrugated boxes for fragile, high-value items (e.g., jewelry, glassware).

- Reusable Value: Many customers reuse rigid boxes for storage (e.g., jewelry boxes, accessory organizers), extending your brand’s visibility long after the product is purchased.

Limitations (vs. Other Packaging Types)

- Higher Cost: Rigid boxes are 2-3x more expensive than folding cartons and corrugated boxes. This makes them impractical for low-margin or bulk products (e.g., budget snacks, basic electronics).

- Storage ChallengesRigid boxes, due to pre - assembled design, consume substantially more space compared to flat - folded counterparts. This poses a major hindrance for small businesses or e - commerce sellers with restricted warehouse room.

7. Why Choose Us for Your Folding Carton, Corrugated Box, or Rigid Box Needs?

As a packaging printing factory with 10+ years of experience, we understand the unique needs of international trade businesses. Here’s why 500+ global brands trust us for their packaging solutions:

✅ Our Own Factory = Unbeatable Price Advantage

Our possession of a 15,000㎡ manufacturing facility (sans middlemen) enables us to tender prices 10 - 15% lower compared to third - party suppliers for folding cartons, corrugated boxes and rigid boxes. Irrespective of whether your requirement is 500 units of bespoke packaging or 10,000 units for mass printing, we channel factory - direct savings your way.

✅ Strict Quality Control = Peace of Mind

Non - negotiable quality demands: each package endures 3 inspection rounds (pre - production, in - printing, post - assembly) to satisfy ISO 9001 and FDA food - packaging international standards. food packaging. Premium materials—food - safe cardboard for folding cartons, moisture - resistant liners for corrugated boxes—are employed to guarantee product integrity.

For proof of our quality, check out our https://www.yucai-box.com/

✅ Fully Customizable = Match Your Brand Perfectly

We offer end-to-end custom packaging solutions:

- Logos & Graphics: Print your brand logo, slogans, or product details via digital printing, offset printing, or UV printing(supports any color—Pantone, CMYK, or custom shades).

- Sizes & Shapes: Tailor dimensions to fit your product (e.g., small folding cartons for lipsticks, large corrugated boxes for furniture).

- Finishes & Add-Ons: Add UV coating, embossing, foil stamping, or window cutouts (ideal for retail packagingto showcase products).

Irrespective of your sector—should you require packaging for cosmetics for a nascent skincare range or packaging for e - commerce for a fledgling tech startup—we'll craft a design attuned to your brand.

✅ Reliable Logistics = Fast, Hassle-Free Delivery

We know international trade delays cost money. That’s why we offer:

- Fast Production: 3-7 days for folding cartons/corrugated boxes; 7-10 days for rigid boxes (faster than industry averages of 10-14 days).

- Global Shipping with DDP Service: We handle customs clearance & taxes for 100+ countries (US, EU, UK, Australia, etc.). You’ll never face unexpected fees or delays.

- Door-to-Door Delivery: Your packages are shipped directly to your warehouse or store—no extra steps for you. Track your order in real time via our [Logistics Tracking Hyperlink].

8. Summary: Matching the Right Packaging to Your Goals

Choosing between folding cartons, corrugated boxes, and rigid boxes depends on your product type, budget, and brand goals. Here’s a quick breakdown to guide your decision:

- Folding Cartons: Ideal for lightweight retail products (cosmetics, snacks, small electronics) where branding and cost-efficiency matter. They offer better graphics than corrugated boxes and lower costs than rigid boxes.

- Corrugated Boxes: Perfect for e-commerce shipping and bulk products (heavy items, large quantities). They provide superior protection vs. folding cartons and lower costs vs. rigid boxes.

- Rigid BoxesFor luxury, high - value items like jewelry, premium gifts, and high - end electronics. Rigid boxes offer unrivaled brand allure compared to folding and corrugated boxes, justifying the steeper cost for premium market placement.

Why We’re Your Best Partner

No matter which packaging type you choose, we’ll deliver:

- Factory-direct prices

- Premium quality (ISO-certified)

- Fully customized designs

- Fast, hassle-free DDP (Delivered Duty Paid)shipping

Ready to get started? Contact our team today via https://www.yucai-box.com/ to get a free quote (no obligation!) or schedule a consultation to discuss your custom packaging needs.

Post time: Sep-24-2025