Within the packaging arena—where margins tighten by the quarter—custom kraft paper boxes have vaulted to the forefront of procurement lists among exporters who must simultaneously safeguard freight, broadcast ecological discipline, and distil a brand narrative into a substrate no thicker than a postcard. Once a mere commodity wrapper, kraft has turned into a silent salesman: its fibrous surface now carries the burden of telling a product’s origin story, calming the eco-anxious shopper, and still surviving the drop-test from a three-metre container slot. Electronics makers, craft chocolatiers, and subscription gift curators alike specify it because the same sheet weight that resists edge-crush accepts soy inks, foil, and debossing without a blister, while costing less per unit than a recycled rigid board of comparable stiffness. The sections that follow retrace the molecular logic of kraft pulp, decode how grammage and flute profile map to cushioning, lay out design heuristics that prevent artwork from fracturing at the score, and—crucially—explain why the final variable is not the paper but the mill: a supplier whose calibration certificates, export documentation, and colour-master retention archives remove weeks from customs clearance can make the difference between a launch window and a detention charge.

1. What is Kraft Paper and Kraft Paper Boxes?

Custom kraft cartons owe their mechanical backbone to the sheet that names them: kraft paper. Pulped by the kraft process—wood chips digested under pressure with a liquor of sodium hydroxide and sodium sulfide—the fibres emerge almost unscathed, long, coarse and interlaced. That intact cellulose lattice translates into high tensile strength and a tear energy that outruns most printing grades, while the absence of aggressive bleaching leaves a warm tawny shade and a velvety matte face. The resulting material is both rugged enough for die-cut scoring and sufficiently porous to accept water-based inks, a combination that underwrites its low-impact, recyclable profile.

2. Diverse Types of Kraft Paper Boxes

Kraft paper boxes’ versatility fits nearly any product or industry. Here are the most common types:

a. Tuck-Top Kraft Boxes

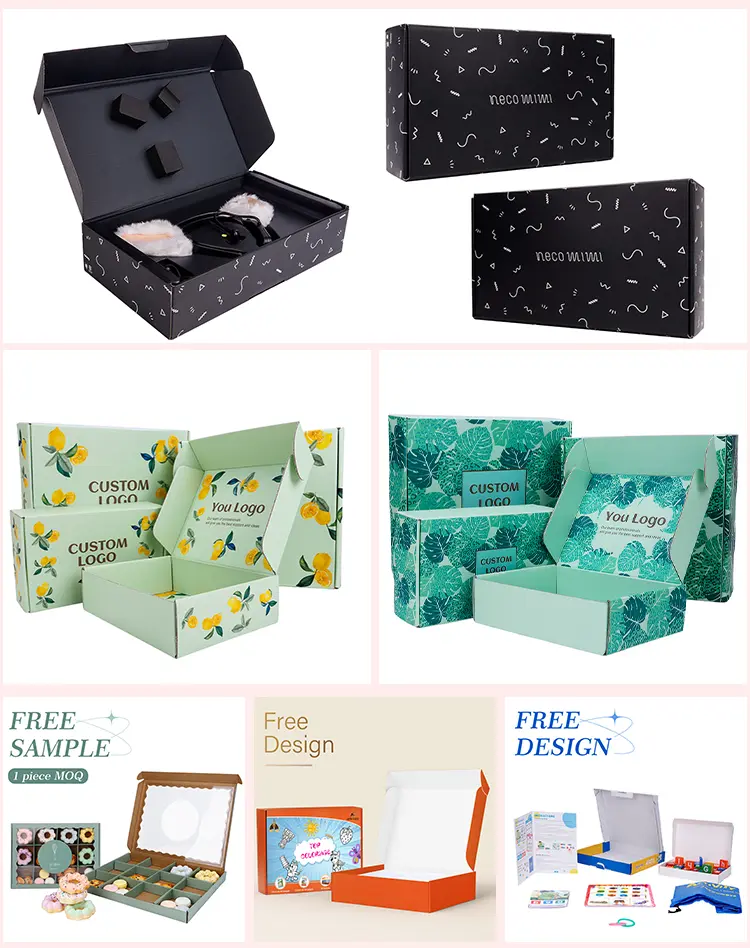

Sized for cosmetics, snacks, or stationery, the carton closes with a self-locking tuck-in lid—tape omitted, assembly reduced to a two-second fold—yet leaves a full four-panel canvas for brand-specific ink: logo, ingredient list, QR code, all litho-printed in one pass. The format rewards e-commerce operations that ship thousands of orders daily; it runs glitch-free on erectors, stacks cubically in totes, and keeps picker touches to a minimum.

b. Rigid Kraft Boxes

Rigid cartons—whose shell of kraft is laminated to an unyielding greyboard core—have become the default armour for high-value, shock-sensitive merchandise: serums bottled in glass, gemstones claw-set in velvet mounts, wafer-thin circuitry. Because the walls neither flex nor buckle, the pack absorbs edge impacts that would otherwise fracture delicate housings; the resulting tactile mass, sharp creases and dead-flat faces turn the moment of reveal into a slow, almost ceremonial sequence. That engineered heft, coupled with printable outer real estate, lets labels broadcast premium cues at freight-forwarder scale, a quiet but decisive differentiator once pallets hit customs-lit shelves from Shanghai to Rotterdam.

c. Kraft Mailer Boxes

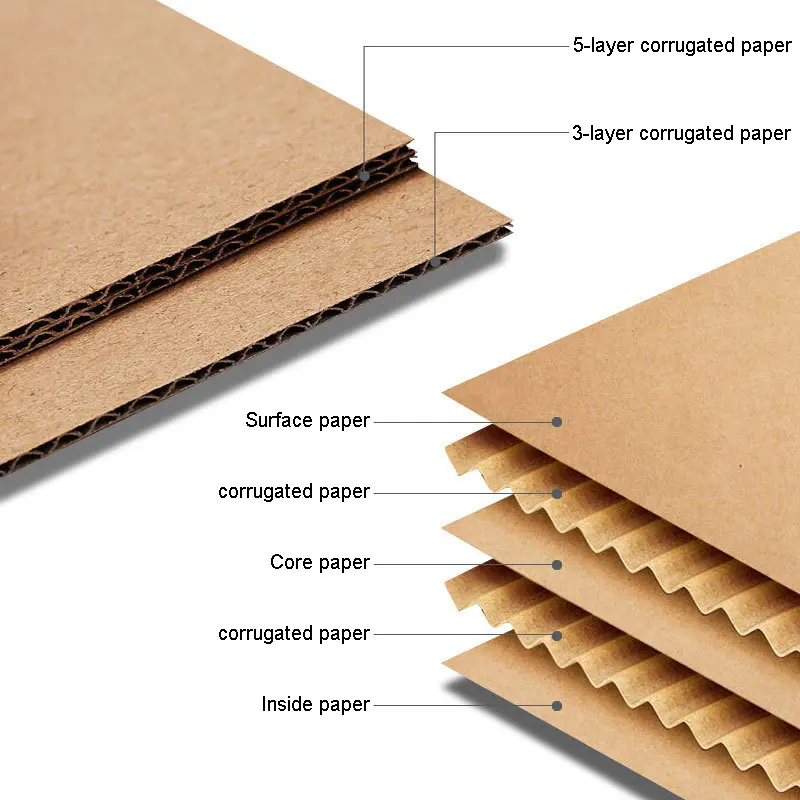

Engineered to endure the rigours of ocean and air freight, these cartons laminate multiple plies of high-grammage kraft into a corrugated lattice whose flute geometry absorbs sudden shocks while repelling airborne moisture and edge-tear propagation. A pressure-sensitive hot-melt strip laid along the closure seam eliminates tape guns and filler, so a single downward press seals the load; the scored flaps fold in a self-indexing sequence that trims packing labour to seconds. That combination of armour-grade protection and speed explains why exporters default to the format when goods must survive multi-modal hand-offs, temperature swings and salt-laden holds for weeks without secondary containment.

d. Kraft Gift Boxes

The line spans half a dozen volume tiers—palm-sized cubes for stocking stuffers, letter-box flats that slide neatly into corporate gift bundles—each exuding a muted, hearth-side warmth that never drifts into rustic cliché. A single waxed ribbon or a discreet sticker grafts onto the matte surface without upsetting the tonal calm, and the substrate itself, once unwrapped, folds flat for the recycling stream or, better, snaps back into service as a catch-all tray, a credential that quietly persuades the eco-audience to keep it in circulation rather than discard it.

3. The Uniqueness and Benefits of Kraft Boxes

For international trade businesses, kraft boxes offer distinct advantages over other packaging materials:

a. Unmatched Sustainability

Fully recyclable and biodegradable, kraft boxes impose a minimal ecological burden across their life cycle. Their advantage sharpens when contrasted with plastics that linger for centuries or with high-gloss cardboard laminated in solvent-based coatings that leach toxic residues; neither rival substrate satisfies the stringent packaging statutes now enforced in the European Union and North America. Nielsen’s 2023 global survey crystallizes the commercial logic: two-thirds of shoppers willingly pay a premium for verifiably sustainable brands, so switching to kraft packaging is less a cost than a calculated wager on repeat purchase and long-term loyalty.

b. Versatile Customization

The tired cliché that kraft is dull collapses the moment a designer treats its earthy brown surface as a deliberate, chromatically silent backdrop: inks saturate it with sharper contrast than bleached board ever allows, metallics glint against it like flares in twilight.Custom kraft paper boxesShort runs demanding photographic gradients or variable data slide effortlessly through a digital press, while continent-spanning orders measured in tens of thousands migrate to offset towers where unit cost plummets and color fidelity locks to GRACoL benchmarks without drift.A blind emboss presses the fibrous sheet into relief that catches sidelight; its inverse, deboss, cups the shadow; foil, registered within those micro-grooves, deposits a molecular skin of gold or pigment that refracts before the eye can name it luxury.

c. Cost-Effectiveness

Kraft paper’s supply chain is already mature, so pulping and sheet-forming demand fewer chemical and energy inputs than bleached alternatives; the cost curve drops accordingly. By shipping straight from our own mill, we erase distributor margins and currency-layer mark-ups, letting the price tag shrink further. Mid-scale overseas labels therefore secure rigid, food-grade cartons without breaching their packaging line budget, diverting the unspent delta to sampling programmes or last-mile logistics.

4. Key Considerations in Kraft Box Design

Designing custom kraft paper boxes requires balancing functionality, aesthetics, and logistics. Keep these points in mind:

a. Printing and Finishing Techniques

Digital ink-jet deposits pigment only where the pixels dictate, so a 200-copy run of a six-colour motiffolds into cartons at the same unit cost as a plain one-colour job; offset lithography, by contrast, waits until the plate is wear-resistant and the paper reel is kilometres long, then repays its makeready investment on the ten-thousandth Swiss or Scandinavian sheet.A brass die that squeezes the substrate upwards leaves a ridge the fingertip can read—embossing—while the same die pressed downwards excavates a shadowed valley called debossing; lay a hair-thin polyester carrier charged with gold or matte-black pigment across the crest of that ridge, let the heated steel cliché kiss it for 0.3 s, and the foil migrates only to the high points, turning the coarse kraft fibres into a lantern of scattered metallic highlights without masking their raw, woody grain.

b. Sustainability Enhancements

Boost eco-credentials: use 100% recycled kraft paper and label it; choose compostable PLA windows; design boxes for reusability (e.g., storage-friendly shapes) with a note encouraging reuse.

c. Logistics for International Trade

Optimize for shipping: keep boxes lightweight and properly sized to cut costs; ensure easy assembly; leave space for labels and customs forms to avoid delays.

5. Why Choose Us for Your Custom Kraft Paper Boxes

For international trade businesses, a trusted manufacturer is essential. Here’s why we’re the right partner:

a. Own Factory: Quality and Cost Control

Our state-of-the-art factory oversees production from sourcing to assembly. No middlemen mean unbeatable prices and strict quality checks—every box meets high standards.

b. Uncompromising Quality

We use premium, sustainably sourced kraft paper. Our printing (digital/offset) ensures vibrant, long-lasting designs, with rigorous checks at every stage to avoid defects.

c. Fully Customizable Solutions

Our designers create boxes matching your vision—size, shape, print, finish. We offer 3D mockups before production, so you can visualize the final product.

d. Reliable International Shipping

We provide fast, secure global shipping. Our team handles double clearance, tax-included services, and door-to-door delivery, avoiding delays and unexpected fees.

Final Thoughts

Tailor-made kraft cartons transcend their utilitarian role; they broadcast brand identity, cocoon fragile contents, and court the planet-minded consumer. Renewable fibres, burst strength that survives humidity swings, and a print-friendly surface converge, equipping exporters to seal overseas orders without second-guessing packaging integrity.

Post time: Oct-29-2025