In the crowded arenas of e-commerce and cross-border trade, the gift box that arrives on a customer’s doorstep often decides the very first impression of a brand. Far more than a simple vessel, the package broadcasts identity, shields fragile contents, and quietly nurtures repeat purchases. Yet the sheer variety of formats can leave retailers unsure where to begin. This overview distills the field into three primary gift-box structures, weighs their distinct strengths, and outlines why Yucai Packaging stands out as a single-source ally for any company seeking reliable, tailored solutions.

1. Guide to Different Gift Box Packaging Types

Each product brings its own demands—fragility, dimensions, brand identity—and the gift box must answer them. Below are the three most common styles, with their strengths and typical applications.

a. Corrugated/Cardboard Gift Boxes:

Corrugated gift boxes—commonly called cardboard gift boxes—are produced from corrugated board, a three-layer sheet whose fluted core is glued between two flat liners. The sandwich structure yields high stiffness and shock absorption, so the boxes reliably shield fragile items in transit or storage.

Key Features:

- Structural Strength: The fluted layer cushions shocks, shielding the contents from impacts, drops and pressure—an advantage that matters in international trade, where shipments face long journeys and repeated handling.

- Lightweight: Despite their durability, corrugated boxes are lightweight, which helps reduce shipping costs (a major advantage for foreign trade businesses looking to cut logistics expenses).

- Customizable: They can be printed with brand logos, colors, and messaging using digital or offset printing. The surface also accepts finishes like matte laminations or UV coatings to enhance aesthetics.

- Eco-Friendly: Most corrugated boxes are made from recycled materials and are fully recyclable, aligning with global sustainability trends and consumer demands for eco-conscious packaging.

How They Compare to Other Types:

Corrugated boxes outlast paperboard or rigid alternatives while keeping costs low. Although they lack the upscale finish of rigid cartons, they shield contents far better than thin paperboard. For brands that put protection before prestige—online merchants shipping everyday items, for instance—corrugated remains the most pragmatic option.

b. Paperboard Gift Boxes:

Paperboard gift boxes are die-cut from dense, single-ply board—thicker than everyday paper yet slimmer than corrugated fibreboard. Their even surface takes print cleanly, folds sharply, and costs little, so brands reach for them across cosmetics, confectionery, and small electronics alike.

Key Features:

- Smooth Aesthetics: The board’s even, glossy face takes ink superbly, letting brands reproduce vivid logos, patterns or product shots without losing detail. Embossing, debossing or foil can then be pressed in for an extra layer of refinement.

- Lightweight and Compact: Unlike corrugated boxes, paperboard boxes are thin and easy to store (they can be shipped flat to save space, reducing storage and shipping costs).

- Cost-Effective: Paperboard is less expensive than rigid material, making these boxes a budget-friendly choice for brands that want a polished look without the luxury price tag.

- Customizable Sizes and Shapes: They can be made in nearly any size or shape—from small square boxes for jewelry to long rectangular boxes for candles or cosmetics.

How They Compare to Other Types:

Paperboard boxes occupy a practical middle ground between appearance and expense. Their smooth faces look cleaner than corrugated board, yet they lack the strength of that material. Compared with rigid boxes, they weigh less and cost less, giving brands a way to lift packaging presence without paying for luxury substrates.

c. Rigid Gift Boxes:

Rigid gift boxes, commonly known as set-up boxes, set the benchmark for luxury packaging. Constructed from dense paperboard—often layered for extra strength—they retain a firm, non-collapsible shape. Their unyielding structure signals premium quality, aligning naturally with high-end brand positioning.

Key Features:

- Premium Feel:Rigid boxes have a substantial, sturdy weight and a luxurious texture—when a customer picks one up, they immediately perceive the product inside as high-value.

- Exceptional Protection: The rigid structure provides excellent protection for fragile or valuable items, as it resists bending, crushing, and impacts.

- High-End Customization: They can be wrapped in specialty materials like linen, velvet, or premium paper, and finished with details like embossing, debossing, foil stamping, or magnetic closures.

- Rigid boxes that open with a sliding lid, hinged top or pull-out drawer give shoppers an immediate ‘wow’, a moment that cements brand loyalty and prompts them to film unboxing videos for social media.

How They Compare to Other Types:

Rigid boxes sit at the top of the packaging hierarchy: their finish feels premium and their walls guard the product, yet this quality comes at the highest price. They outlast and outshine paperboard cartons, and although they match corrugated fibreboard for protection, they add a sense of luxury that plain brown board cannot deliver. For labels battling for attention in crowded segments—luxury skincare or fine jewellery—the up-front cost of a rigid box is quickly repaid through stronger brand image and repeat purchases.

2. Benefits of Gift Box Packaging

Whatever style you pick, gift-box packaging does more than simply contain the product; it can lift sales, burnish brand image, and advance your export strategy.

a. Enhances Brand Identity and Recognition

Gift boxes act as a blank canvas for your brand. Once your logo, colours and message are added, the plain container becomes a marketing asset. Each sight or use of the box reminds the customer of your company, reinforcing recognition. A luxury skincare label that ships products in a rigid box stamped with its signature gold emblem, for instance, projects a coherent, memorable image linked to quality.

b. Protects Products During Transit

In cross-border commerce, goods frequently arrive cracked, dented, or soaked. Sturdy gift boxes—corrugated or rigid—cushion shocks, block moisture, and survive rough conveyor belts, cutting the likelihood of costly returns and one-star reviews. Research by the Packaging Federation shows that firms switching to these boxes reported 30 % fewer damaged deliveries, simultaneously preserving cash, time, and customer confidence.

c. Supports Sustainability Goals

Corrugated, paperboard and rigid paperboard—the materials most gift boxes are made from—can be recycled or already contain recycled fibre. Opting for these greener boxes lets a brand ride the global sustainability wave and speak directly to shoppers who weigh environmental impact in their purchase decisions.A food company that ships its products in recycled paperboard gift boxes, for instance, can label itself 'sustainable' and draw in consumers who put environmental responsibility at the top of their list.

3. Yucai Packaging: Your Packaging Solution

Selecting a gift-box supplier for international trade hinges on three non-negotiables: consistent quality, flexible customization, and dependable delivery. Yucai Packaging satisfies each requirement and goes further, which is why companies across continents treat us as their default partner.

a. Our Own Factory: Control Over Quality and Cost

Unlike middlemen or third-party suppliers, we own our state-of-the-art manufacturing facility. This gives us full control over every step of the production process—from sourcing raw materials to printing, cutting, and assembling your gift boxes. By eliminating middlemen, we cut out unnecessary markups, allowing us to offer unbeatable prices without compromising on quality. Our factory also adheres to strict quality control standards: every gift box is inspected for defects such as misprints, weak seams, or uneven finishes before it leaves our facility, ensuring you receive only the best products.

b. Uncompromising Quality: Materials That Last

We use only premium materials for our gift boxes:

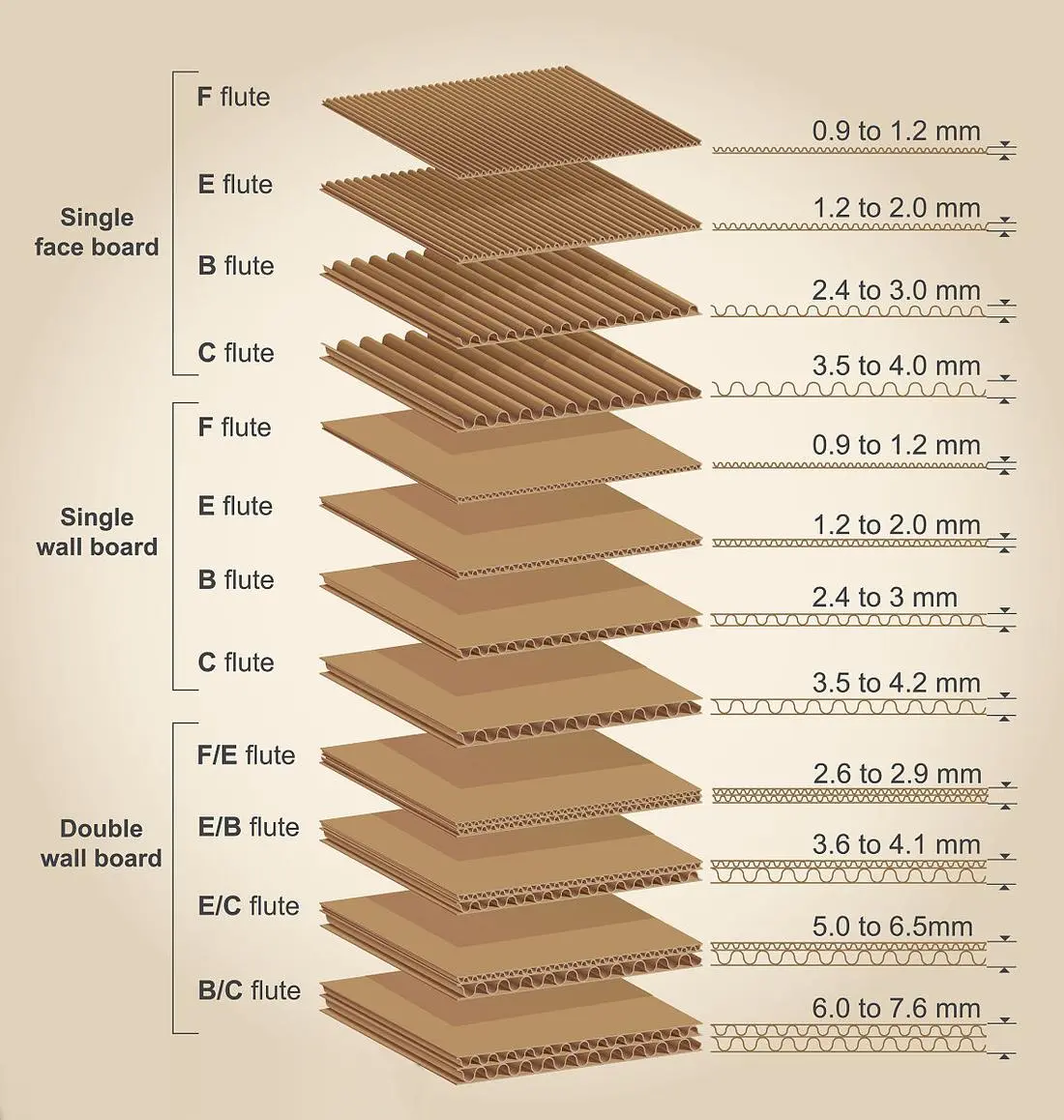

- Corrugated boxes: High-grade corrugated material with strong flutes (B-flute for medium protection, E-flute for lightweight strength) to ensure durability during shipping.

- Paperboard boxes: Thick, smooth paperboard that holds prints well and resists tearing.

- Rigid boxes: Reinforced rigid paperboard wrapped in specialty materials (e.g., premium paper or fabric) to create a luxurious feel.

The gift boxes are printed with low-impact inks and bonded with solvent-free adhesives, so they remain premium while meeting international environmental standards—an attribute that resonates with sustainability-minded buyers.

c. Fully Customizable Solutions: Your Vision, Our Expertise

Recognising that no two brands are identical, we provide gift boxes that can be tailored from top to bottom. A team of seasoned designers collaborates with you to translate your concept into reality, whatever your requirements:

- Custom sizes and shapes: From small jewelry boxes to large gift baskets.

- Branded printing: Logos, colors, patterns, or messaging using digital, offset, or screen printing.

- Premium finishes: Embossing, debossing, foil stamping, UV coatings, or magnetic closures.

- Specialty materials: Linen, velvet, recycled paper, or window cutouts.

Post time: Nov-03-2025