To choose the right box for shipping, consider the product's size, weight, fragility, and the conditions it will encounter during transit. Select a box that closely fits the product to minimize movement and potential damage, while also allowing for adequate cushioning material. Factor in the box's strength and durability, opting for reinforced or weatherproof options if needed. Finally, consider the cost and ease of use, and whether custom printing or protective features are necessary for your specific needs.

1.Size and Fit:

Measure your product:

Accurately measure the length, width, and height of your product, including any handles or extended parts.

Enhance protection:

Choose a box that allows for a few inches of cushioning material (like bubble wrap or packing paper) on all sides of the product.

Reserve sufficient space:

Overly large boxes can cause items to shift and get damaged, while undersized boxes can lead to crushing.

Consider product grouping:

If shipping multiple items, consider how they will be packed together and choose a box that accommodates the combined size and weight.

2.Strength and Durability:

Corrugated box:

This is a popular choice due to its strength, lightweight nature, and affordability.

Reinforced boxes:

For heavier or fragile items, consider reinforced boxes that offer extra protection against impacts and stacking. You can add insert in your box to protect your products.

Weatherproof options:

If shipping in humid or wet conditions, opt for boxes with weatherproofing capabilities. Usually, the surface of the box is coated with a film, which serves to prevent moisture.

Weight limits:

Be mindful of the maximum weight capacity of the box to prevent breakage during transit.

3.Common types of packaging:

1) Corrugated box:

A Corrugated box is often used as outer packaging for products with large volume or heavy weight. The custom corrugated material is commonly used to make transportation cartons.

Construction: Corrugated box is composed of multiple layers of materials: the innermost layer is the liner paper, the outermost layer is a sheet of paper, and there is at least one layer of wavy inner core in the middle. There are at least three layers that are bonded together to form a stable triangular structure.

Strength: This design has a very strong function of shock absorption and cushioning, and can well protect the products inside during transportation.Much stronger and more durable than cardboard, offering greater protection during shipping.

Application fields:

- Packaging Industry: Corrugated paper is widely used in the packaging of various products, such as household appliances, food, cosmetics, etc.

- Construction industry:Corrugated paper can be used for sound insulation and heat preservation in construction.

- Art Design: Corrugated paper can also be used as an artistic design material to create various handicrafts, decorations, etc.

2) Cardboard box:

Cardboard boxes are often used for inner packaging, suitable for products with small volume and light weight, commonly use white paperboard box .

Construction : In terms of material, the cardboard box only has one layer of cardboard, unlike corrugated material which has many layers. Therefore, the card box is thin.

Strength: Not as strong or durable as corrugated boxes.

Application fields: individual cardboard boxes are Used for packaging lightweight and small-sized products. Commonly found in the packaging of retail products. The following are the common application fields:

- Gift Packaging

Cardboard box can be made into a beautiful small package, which can be used to wrap holiday gifts, birthday gifts, etc. You can also add some crafts on the surface of the box, such as gold stamping, embossing, etc., to make your box look more exquisite.

- Food Packaging

Suitable for packaging foods like biscuits, chocolates, and tea. Print your logo and design to enhance your brand influence.

- Pharmaceutical Packaging

The cardboard box is also suitable for packaging medicines. Clearly print the information of the medicine to ensure its safety during transportation.

- Cosmetics Packaging

Cardboard box is very suitable for packaging cosmetics. Its exquisite printing effect and lightweight characteristics are often used for packaging products like perfumes and cosmetics. Suppliers can also enhance the packaging grade by adding more craftsmanship.

- Electronic Product Packaging

Used to protect the transportation safety of electronic products, such as headphones, charging cables, and power banks. You can also add an inner liner inside the box to protect the product during transportation.

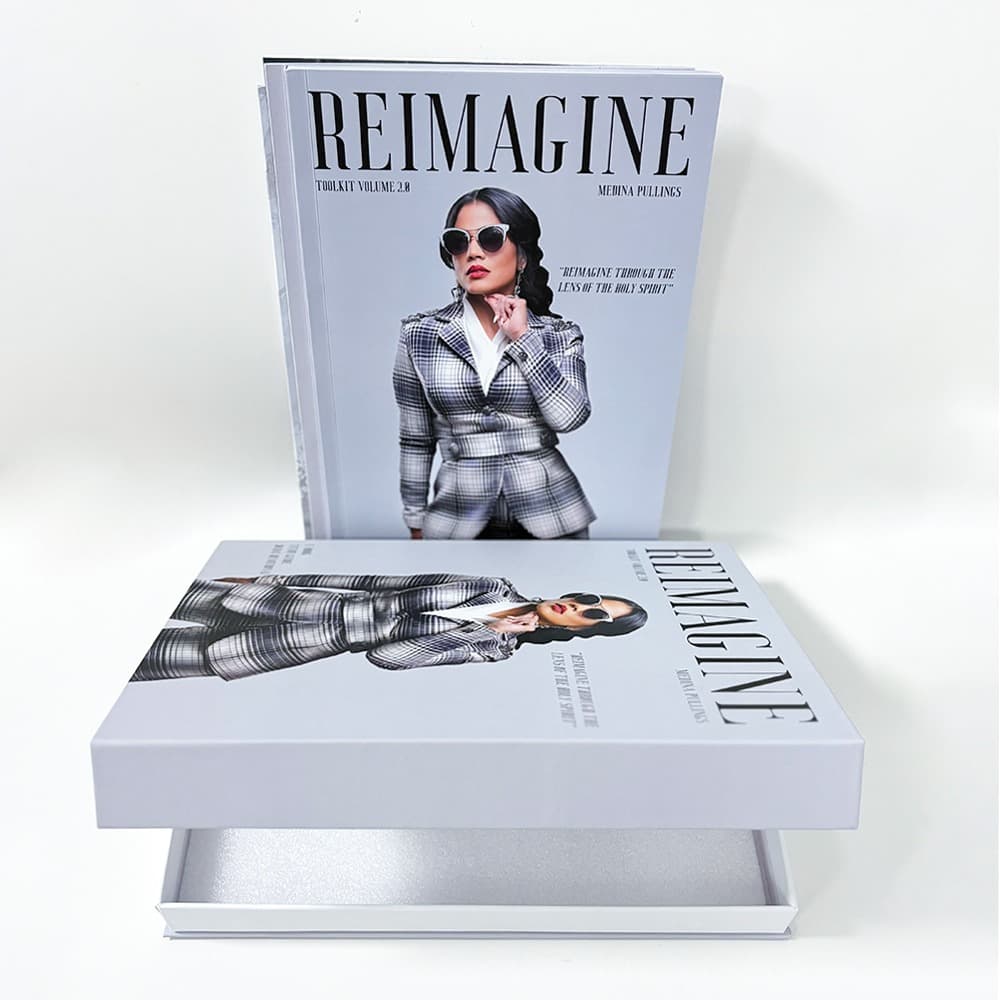

- Rigid box:widly used for luxury packing , such as watch,jewelry ,high quality watch.could improvethe company profile well.

Construction: Rigid box is composed of multiple layers of materials: the middle layer is the rigid paper board with thickness 2Mm and 3MM., the outermost layer is a sheet of paper, inside widely also all kinds of paper with printing.

Strength: Much stronger and more durable than cardboard and corrugated box,also with high quality, meanwhile offering greater protection during shipping.

Application fields:

- Packaging Industry: rigidboxwidely used in the high quality goods,such as watch ,clothes.

- Construction industry:Corrugated paper can be used for sound insulation and heat preservation in construction.

4.Confirmtransportation and storage requirements

- Transportation methods:

Long-distance transportation, Requires shock-resistant and pressure-resistant packaging, such as reinforced cardboard boxes or wooden crates.

- Delivery or air freight:

Consider using lightweight and protective packaging, such as bubble wrap wrapped in a cardboard box.

- Storage environment:

Damp environment, Requires moisture-proof packaging materials, such as waterproof boxes or aluminum foil bags.

- High-temperature environment:

Select materials that can withstand high temperatures to prevent packaging from deforming or getting damaged.

5.Evaluate packaging costs

- Material costs: The costs of different materials vary significantly, and the choice should be made based on the budget.

- Production cost:Complex designs and processes may increase production time and costs.

- Transportation cost: Lightweight packaging can reduce transportation expenses, but it is necessary to ensure adequate protection. Lightweight packaging can reduce transportation expenses, but it is necessary to ensure adequate protection.

- Craftcost:in order to improve company profile,normally has some craft on the box ,like hot stampings,and spot uv,and embossed,this will up the cost ,but if more qty,this cost could be ignore,so sutit for huge qty

- Material choose :also has different material could use,widely cheap one is coated paper,kraft paper,this could save cost .

In a word,when you want to choose one box to pack your goods,need to consider above information,from material,craft and using environment and qty and the packing goods,then choose one right suit packing box to suit your goods.

Post time: Aug-20-2025