In the current global e-commerce scenario, packaging is not merely a container. It actually constitutes a crucial part of your brand identity, the experience of customers, as well as the operational efficiency. Picking the appropriate corrugated boxes can have a notable influence on your shipping costs, the safety of products, and the environmental impact. As a prominent manufacturer and supplier within the packaging industry, we are dedicated to assisting you in making well-informed decisions that can enhance your business. This thorough guide delves into all that you need to be aware of regarding corrugated boxes, ranging from basic classifications to sophisticated customization alternatives.

1.Gaining an Understanding of Corrugated Boxes: Their Varied Types and Diverse Applications

Corrugated boxes stand as the gold standard within protective packaging. They are crafted via an innovative process which brings about a layered structure made up of fluted paper placed between linear boards. This particular construction gives rise to air columns that offer remarkable cushioning, effective temperature insulation, and good shock absorption. These qualities are of great importance when it comes to meeting the challenges faced in modern shipping.

Single-Wall Corrugated Boxes

The single-wall boxes, which happen to be the most versatile option that is also widely utilized, come with a single layer of fluting sandwiched between two linerboards. These boxes possess an excellent ratio of weight to strength, making them highly suitable for:

- E-commerce shipments

- Retail packaging

- Food and beverage packaging

- Consumer goods

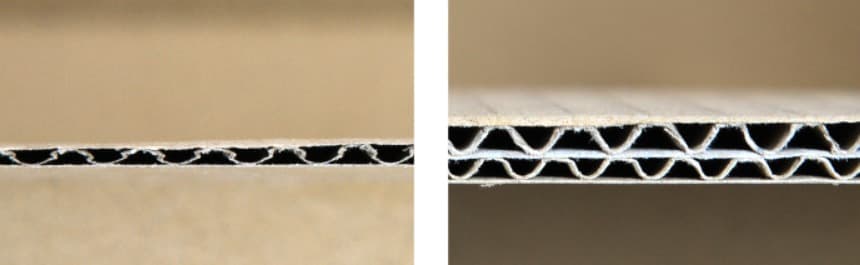

Show an image that presents the single-wall structure.

Double-Wall Corrugated Boxes

The enhanced protection is achieved by having two fluted layers that are sandwiched among three linerboards. These boxes present the following:

The stacking strength is 50% higher than that of the single-wall.

- Superior puncture resistance

It is perfect for items that are on the heavier side, weighing between 15 and 30 kg.

It is highly suitable for shipping over long distances.

Triple-Wall Corrugated Boxes

The packaging heavyweights are characterized by three fluted layers along with four linerboards. Their remarkable durability renders them appropriate for:

- Industrial components

- Automotive parts

- Bulk agricultural products

Substitution for wooden crates

Specialty Corrugated Solutions

Apart from the standard boxes, we also present specialized configurations such as:

Die-cut boxes that have custom shapes

Boxes that have the characteristic of self-locking and do not need tape.

- Water-resistant variants

2.Material Science: Choosing the Right Composition

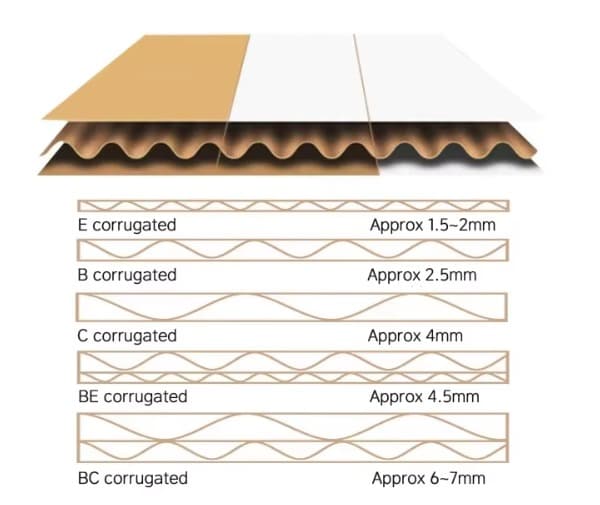

The performance of corrugated boxes hinges on two really important elements, namely flute profiles and the quality of linerboard. Having a good understanding of these components can help to ensure that you make an optimal selection to meet your specific requirements.

A-Flute (5mm height)

Exceptionally good cushioning characteristics

Exceptionally good vertical compression strength

Perfect for fragile items such as glassware, and also suitable for ceramics as well as electronics.

Recommended for use in: Retail displays as well as protective packaging.

B-Flute (3mm height)

A greater quantity of flutes for each foot.

It shows remarkable resistance against puncture.

A flat surface is utilized for the purpose of high-quality printing.

Ideal for canned goods as well as point-of-sale displays.

C-Flute (4mm height)

Properties of balanced protection

- Good stacking strength

The material that is most commonly used for shipping boxes.

The application is universal across various industries.

Micro Flutes of the E, F, and N profiles

- Superior printing surface

- Space-efficient storage

- Premium aesthetic quality

It is ideal in relation to retail packaging, as well as for cosmetics and consumer electronics.

Linerboard Selection Guide

Kraft Linerboard

- Virgin fiber composition

The ratio of strength to weight is the highest.

- Natural brown appearance

Exceptionally good resistance to moisture

Test Linerboard

- Recycled content composition

An option that is friendly to the environment

- Cost-effective solution

Consistent quality in performance

White-Top Linerboard

- Bleached surface layer

- Superior printing surface

- Enhanced brand presentation

- Food-grade compatibility

Sophisticated Combinations of Materials

Our exclusive material formulations consist of:

- Water-resistant coatings

- Anti-static treatments

Food-grade materials that comply with FDA regulations.

- Humidity-resistant barriers

In the highly competitive market of today, the generic packaging solutions simply fall short. Our extensive customization capabilities work to turn ordinary boxes into potent brand assets.

3.Customization Excellence: Beyond Standard Packaging

Size Optimization

Our technical team makes use of advanced CAD systems to produce packaging that is perfectly fitted. This packaging has the characteristic that:

It cuts down the usage of materials by as much as 30%.

- Minimizes shipping volume

- Eliminates product movement

Reduces the total costs associated with shipping.

Structural Innovation

We design boxes featuring:

- Integrated handles and grips

- Easy-open mechanisms

- Reusable closure systems

Compartments that are specific to a product

Printing Technologies

We present a variety of printing solutions that can meet your specific requirements.

High-resolution flexographic printing can be described in a more detailed manner. It pertains to a type of printing process that is characterized by a relatively high level of resolution. This particular printing method has its own unique features and applications within the realm of printing technology. It involves the use of specific equipment and materials that work together to achieve the desired high-resolution output. The intricacies of high-resolution flexographic printing are such that it demands careful consideration of various factors, including but not limited to the quality of the printing plates, the type of inks employed, and the precision of the printing machinery. Each of these elements plays an important role in determining the final quality of the printed output, which is expected to exhibit a high degree of clarity and detail.

Litho-lamination aimed at achieving premium finishes.

Digital printing is utilized for short runs.

Specialty coatings as well as varnishes

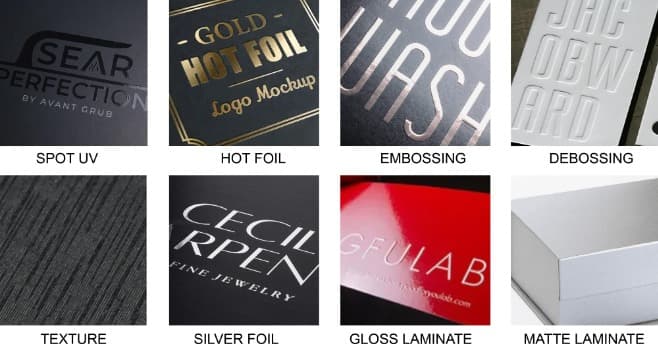

Brand Enhancement Features

CMYK printing along with specialty color printing

- UV spot coatings

- Embossing and debossing

- Scratch-and-sniff coatings

Sustainable Customization

Eco-friendly options include:

- Soy-based inks

- Water-based coatings

Optimization of recycled content

- Biodegradable additives

4.Industry-Specific Solutions

E-commerce Optimization

Automated packaging systems of an appropriate size

- Branded unboxing experiences

- Returns-friendly designs

Space-conserving nesting alternatives

Food and Beverage

- Grease-resistant coatings

- Moisture barrier options

The designs related to temperature maintenance

Electronic items as well as fragile ones

- Static-dissipative materials

The integration of custom cushioning.

- Humidity indicator options

- Tamper-evident features

Retail Ready Packaging

- Shelf-ready designs

Enhanced capabilities in relation to graphics

- Easy stocking features

- Security enhancements

5.Conclusion: Why choose us?

When it comes to choosing the appropriate corrugated boxes, one has to take into careful account the specific needs of the products, the requirements for shipping, as well as the objectives of the brand. The packaging solution that is considered ideal ought to offer the best possible protection. At the same time, it should also aim to minimize both the costs and the impact on the environment.

At Shanghai Yucai Industrial Co., Ltd, we bring together our technical know-how and creative innovation in order to come up with packaging solutions that:

Lower the shipping costs by means of an optimized design.

Improve the perception of the brand by means of an excellent presentation.

Reduce the environmental impact by means of making a smart choice regarding material selection.

Enhance operational efficiency by means of intelligent design.

Our team, which consists of packaging engineers and design specialists, stands prepared to assist you in the development of customized solutions. These solutions are designed to handle your distinct challenges as well as the opportunities that come your way.

Are You Prepared to Make Transformations to Your Packaging?

Examine our wide variety of packaging solutions.

Thousands of customers have been satisfied as they have transformed their packaging by using our novel solutions. Let us collaborate to bring about something truly remarkable.

Post time: Aug-26-2025