In the hyper-visual world of beauty, the box is just as important as the bottle inside. It’s a silent storyteller, a tactile promise of the quality and luxury that awaits. The right printing technique can transform a simple piece of cardboard into a coveted object, making a product leap off the shelf and into a customer's hands. Choosing the perfect printing method is not just a technical decision; it's a critical brand statement. It’s the final, crucial touch that defines the entire packaging experience, turning a container into a piece of art that can captivate, communicate, and convert.

What is Offset Printing and Why is it the Gold Standard for Cosmetic Boxes?

When it comes to achieving crisp, vibrant, and consistent color printing for cosmetic boxes, offset printing reigns supreme. This renowned printing technique involves transferring ink from metal plates to a rubber blanket, which then rolls the image onto the packaging surface. This indirect process results in exceptionally sharp details and rich, accurate colors that are difficult to match. For any brand that relies on precise color matching to maintain its identity, offset is the most reliable choice.

The primary advantage of offset printing is its unparalleled print quality and consistency over large production runs. Once the initial setup is complete, each subsequent piece is a perfect replica of the first. This makes it a highly cost-effective solution for high-volume packaging projects. If you are producing thousands of units of cosmetic packaging, the per-piece cost of offset printing becomes very low, offering premium quality without a premium price tag on each box. This makes it the go-to printing method for established beauty brands that require both quality and scale.

When is Digital Printing the Right Choice for Your Packaging?

While offset is the king of large-scale production, digital printing is the agile and versatile prince. This printing technology works much like a desktop inkjet printer, applying ink directly onto the packaging material from a digital file. This eliminates the need for printing plates, which drastically reduces setup time and costs. For brands needing short runs, limited edition releases, or prototypes, digital printing is the ideal, cost-effective solution.

One of the most exciting features of digital printing is its capability for variable data printing. This allows for each box to be customized with unique text or graphics, such as a customer's name or a unique code, without slowing down the printing process. This opens up incredible possibilities for personalization in promotional packaging. While the print quality of modern digital printing is excellent and getting closer to offset, its main strength lies in its flexibility and speed, making it perfect for emerging brands and targeted marketing campaigns.

How Does Screen Printing Add a Unique Touch to Packaging?

Screen printing, also known as silkscreen or stencil printing, is a classic printing technique that offers a distinct and tactile result. The process involves pushing ink through a mesh screen, or stencil, onto the packaging surface. Because this method can lay down a very thick and opaque layer of ink, it produces incredibly vibrant, bold colors that stand out with a slightly raised texture.

This printing method is particularly effective for bold, graphic designs with a limited number of colors. It works exceptionally well on a wide variety of packaging materials, including paper, plastic, and even glass. For a cosmetic brand looking to achieve a handcrafted, artistic, or retro look and feel, screen printing can add a layer of authenticity and character to its product packaging that other methods can't replicate. It’s perfect for creating a statement piece of unique packaging.

What Makes UV Printing a Game-Changer for Cosmetic Packaging?

UV printing is a form of digital printing with a high-tech twist. In this process, special inks are applied to the packaging, and then they are instantly cured, or dried, by exposure to ultraviolet (UV) light. This instantaneous curing process prevents the ink from soaking into the material, leaving it sitting on the surface. The result is incredibly sharp, crisp details and stunningly vibrant colors.

This printing technology is a favorite in the cosmetic packaging world for several reasons. The cured ink is highly durable and resistant to scratching and fading. It can also be used to create a beautiful, glossy finish. One of the most popular applications is Spot UV, where a glossy varnish is applied to specific areas of the design—like a logo or pattern—to create a striking contrast against a matte background. This eye-catching effect adds a layer of sophistication and makes the packaging feel more interactive and luxurious.

How Can Foil Stamping Elevate Your Brand's Packaging?

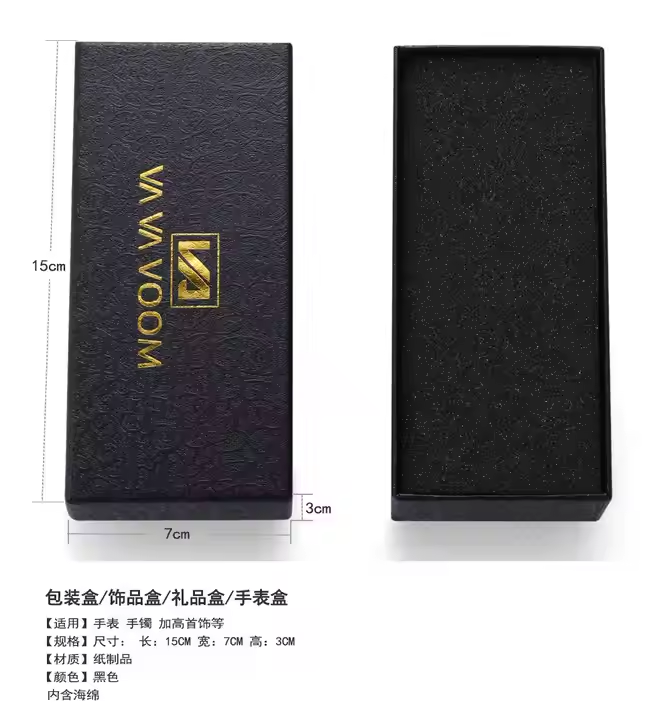

For brands looking to add a touch of undeniable luxury to their packaging, foil stamping is the answer. This is not a printing process that uses ink, but rather a specialty finishing technique. It involves using heat and pressure to apply a thin layer of metallic foil to the packaging surface. The result is a brilliant, shimmering finish that catches the light and immediately signals a high-end product.

Foil stamping is perfect for highlighting key elements of a box design, such as the brand logo, product name, or a decorative border. Available in a wide range of colors beyond the traditional gold and silver, including rose gold, copper, and even holographic finishes, it allows for incredible creativity. This technique is a hallmark of premium packaging in the cosmetic industry, instantly elevating the perceived value of the product before the box is even opened.

What is the Tactile Appeal of Embossing on Cosmetic Boxes?

Great packaging engages more than just the sense of sight; it should also be a tactile experience. This is where embossing comes in. Embossing is a finishing process that creates a raised, three-dimensional effect on the surface of the packaging. A metal die is used to press into the paper, pushing the design up from the surface. The opposite effect, called debossing, impresses the design into the material.

The simple act of adding an emboss to a logo or pattern creates a powerful sensory cue. It invites the customer to touch and interact with the packaging, making it feel more substantial and of higher quality. This subtle detail adds depth and sophistication to cosmetic boxes, transforming a flat design into a dynamic, touchable piece of art. When combined with other techniques like foil stamping, embossing can create truly stunning and memorable high-end packaging. The way the packaging feel in the hand is a crucial part of the luxury experience.

Exploring Gravure Printing for Ultimate Precision and Quality

For the absolute pinnacle of print quality in the packaging industry, many turn to gravure printing, also known as rotogravure printing. This printing method uses a cylinder that has been intricately engraved with the design. The cylinder rotates through a bath of ink, and the recessed cells fill with ink, which is then transferred directly to the packaging material at high speed.

Gravure printing produces flawless, photo-quality images with exceptional detail and color depth. It is capable of creating perfect gradients and continuous tones, making it ideal for the most demanding luxury packaging projects. However, the cost of creating the engraved cylinders is very high, which means this printing method is only cost-effective for extremely high-volume production runs, often in the hundreds of thousands or millions. For ultra-premium, mass-market cosmetic products, gravure ensures that every single box is a masterpiece.

Beyond Traditional Methods: Is 3D Printing the Future of Packaging?

While not yet a mainstream method for mass production, 3D printing is an exciting printing technology that is beginning to make its mark on the packaging world. 3D printing builds objects layer by layer from a digital file, allowing for the creation of incredibly complex and intricate shapes that would be impossible with traditional methods.

Currently, its primary role in packaging is for creating rapid prototypes. A brand can quickly 3D print a model of a new bottle or container to test its ergonomics and appearance before investing in expensive molds. However, as the technology becomes faster and more affordable, it holds the potential to create truly bespoke and unique packaging structures, such as custom-fit inserts or limited-edition artistic containers. While you won't see mass-produced cosmetic packaging made with 3D printing just yet, it's a space to watch for future innovations.

How to Choose the Right Printing and Packaging Partner?

Navigating the world of printing and packaging can be complex, but you don't have to do it alone. Choosing the right printing partner is crucial to bringing your vision to life. A good partner will be more than just a printer; they will be an expert consultant who can advise you on the best printing method and finishing techniques for your specific project, budget, and brand goals.

When evaluating printing companies, look for experience in the cosmetic industry. They will understand the importance of color consistency and the nuances of creating premium packaging. Ask to see samples of their work and be clear about your expectations. The right partner will work with you to create stunning custom packaging boxes that not only protect your product but also tell your brand's story beautifully, ensuring your product packaging makes a powerful and lasting impression.

Key Takeaways to Remember

- Offset Printing for Quality at Scale: Ideal for high-volume orders, offset delivers superior, consistent color and is highly cost-effective for large runs.

- Digital Printing for Flexibility: Perfect for short runs, prototyping, and personalization, offering quick turnarounds with no plate costs.

- Finishing is Key to Luxury: Techniques like foil stamping and embossing are not just add-ons; they are essential for creating a tactile, premium, and memorable packaging experience.

- UV Printing Adds a Modern Pop: For vibrant, durable, and glossy results, UV printing offers a modern edge, with Spot UV being a popular choice for creating visual contrast.

- Match the Method to the Project: There is no single "best" printing method. The right choice depends on your order volume, design complexity, budget, and desired brand perception.

- Partner with an Expert: Work with an experienced packaging supplier who can guide you through the options to create the most effective and eye-catching packaging for your brand.

Post time: Dec-30-2025