In a world filled with square and rectangular boxes, the elegant, cylindrical shape of a paper tube immediately captures attention. This unique form of packaging is more than just a container; it's a statement. It tells a story of quality, sustainability, and thoughtful branding. As a leading paper tube manufacturer with over 15 years of experience, I've seen firsthand how switching to custom paper tube packaging can transform a product's presence on the shelf and in the hands of a customer. This guide is your all-access pass to understanding the power of the paper tube. Whether you're in the cosmetic industry, food, or apparel, you'll discover why this versatile, eco-friendly, and highly customizable packaging solution might be the perfect fit for your brand.

What Exactly Is Paper Tube Packaging?

At its heart, paper tube packaging is a type of cylinder packaging created by spirally winding multiple layers of paper or paperboard around a mold. These layers are bonded together with adhesive, resulting in a strong, durable, and hollow cardboard tube. While the concept is straightforward, the execution allows for incredible versatility in size, strength, and design. You might see this style referred to as cardboard tube packaging, composite cans, or paper canisters. It's a significant step up from standard paper boxes in terms of structural integrity and visual appeal.

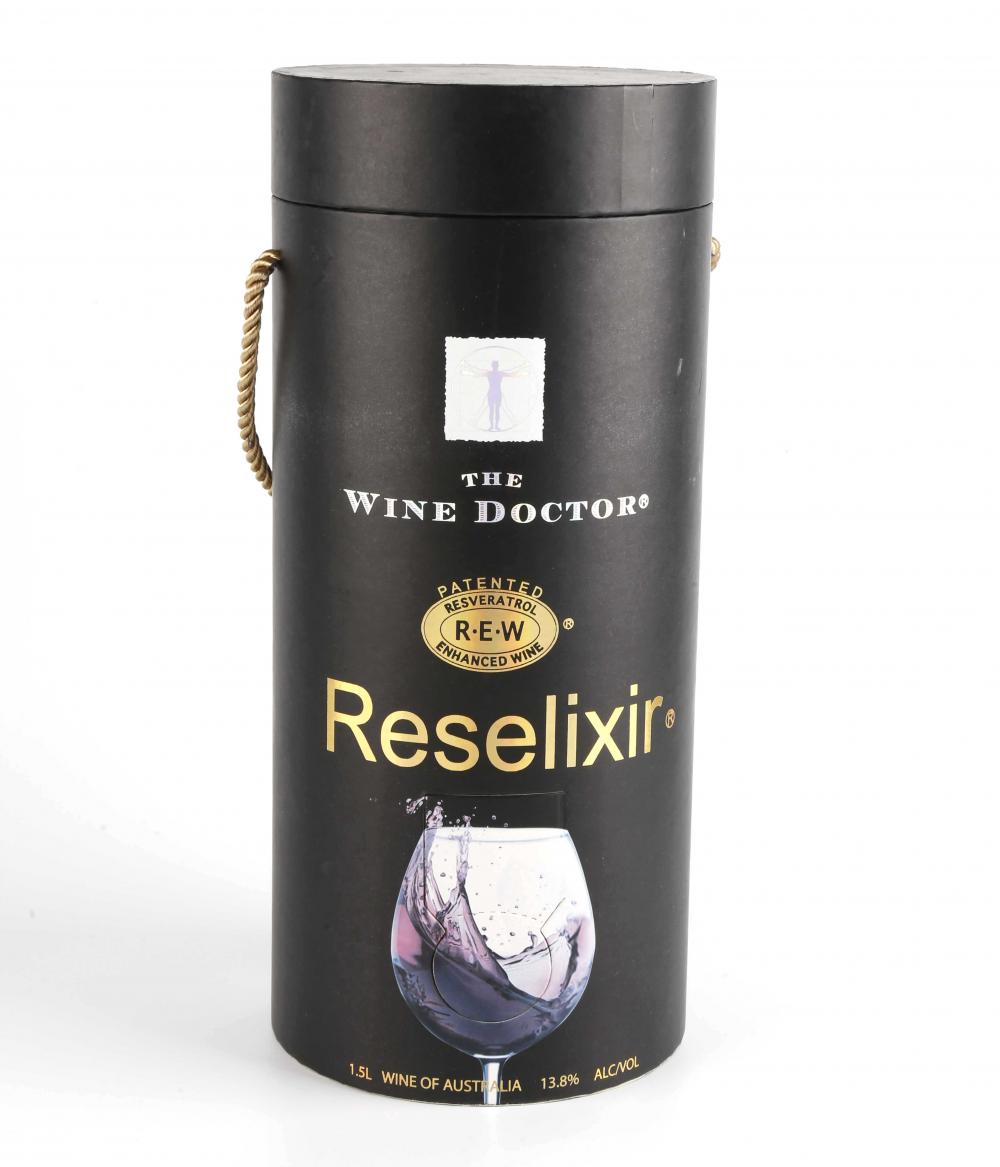

This type of packaging is engineered for both protection and presentation. The manufacturing process allows us to control every aspect—from the inner diameter and length to the wall thickness—to meet your specific packaging needs. Unlike a standard folding cardboard box, the unique shape of a paper tube provides a 360-degree canvas for branding. This allows for creative and immersive packaging design that tells your brand's story from every angle. The result is a piece of product packaging that feels substantial, looks premium, and stands out in a crowded market.

The versatility of tube packaging is one of its greatest strengths. It can range from simple, one-piece mailing tubes designed for shipping documents to complex, multi-piece telescoping tubes for luxury goods. The materials can vary from natural brown kraft paper to vibrant, custom-printed wraps with specialty finishes. This adaptability makes the paper tube an ideal packaging solution for businesses seeking a distinctive and functional way to present their products.

Why Are Kraft Paper Tubes a Top Choice for Eco-Friendly Brands?

When you think of natural and eco-friendly packaging, kraft paper is often the first material that comes to mind. A kraft paper tube has a rustic, organic appeal that instantly communicates a commitment to sustainability. Kraft paper is produced from wood pulp in a process that results in very strong paper fibers. Crucially, it is unbleached, which gives it that signature brown color and means fewer chemicals are used in its production. This makes it a cornerstone of environmentally friendly packaging.

Kraft tubes are celebrated for their green credentials. They are typically made from a high percentage of recycled paper and are themselves fully recyclable. This aligns perfectly with a circular economy model, where materials are kept in use for as long as possible, reducing waste and the demand for virgin resources. For brands in the wellness, organic food, or artisanal goods sectors, this type of kraft packaging is not just a container; it’s an extension of the brand's ethos. The packaging itself becomes a symbol of the natural product inside.

But choosing a natural look doesn't mean sacrificing design. A kraft paper tube provides a fantastic, textured canvas for branding.

- Minimalist Design: A simple one-color print (often black or white) creates a striking, modern, and clean aesthetic.

- Full-Color Printing: We can apply a white base layer to the kraft paper before printing, allowing for vibrant, full-color graphics that pop against the natural background.

- Premium Finishes: Combining the rustic texture of kraft paper with elegant finishes like foil stamping or embossing creates a beautiful contrast, blending natural simplicity with a touch of luxury. For example, a kraft paper candle tube can be both earthy and sophisticated.

How Can I Customize My Cardboard Tube Packaging?

The true magic of cardboard tube packaging lies in its incredible potential for customization. This is where you can truly let your brand's personality shine. A custom paper tube can be tailored to your exact specifications, transforming it from a simple container into a bespoke piece of art that enhances your product packaging and delights your customers. As a manufacturer of custom packaging, this is the part of the process I find most exciting.

The ability to customize goes far beyond just printing a logo. You have control over every element of the paper tube. We can create a custom size to ensure a perfect, snug fit for your product, which not only looks better but also provides superior protection. You can choose the style of the tube, whether it's a simple tube with a cap, a two-piece telescoping tube, or even a shaker top for spices or powders. The possibilities for custom cardboard are nearly limitless.

Here is a quick look at some key customization options:

| Customization Area | Description | Impact on Your Brand |

|---|---|---|

| Size & Structure | Custom diameter, height, and wall thickness. Multiple styles like telescoping or shaker tops. | Ensures a perfect fit, enhances protection, and creates a unique unboxing experience. |

| Materials | Choice of outer wrap papers: standard white, natural kraft paper, or specialty textured papers. | Defines the look and feel of your packaging, aligning it with your brand's aesthetic (e.g., rustic, luxury). |

| Printing | Full-color CMYK, Pantone (PMS) spot colors, and printing on the inside of the tube. | Allows for vibrant, brand-accurate designs that capture customer attention. |

| Finishes | Matte/gloss lamination, soft-touch coating, spot UV, foil stamping, embossing/debossing. | Adds tactile and visual effects that elevate the perceived value and create a premium feel. |

Are Paper Tubes a Truly Eco-Friendly Packaging Solution?

Yes, absolutely. In an age where consumers are actively seeking sustainable packaging, paper tubes stand out as an excellent eco-friendly choice. Their green credentials are one of the primary reasons for their surge in popularity across various industries. This commitment to the environment is a powerful way for a brand to connect with the values of modern consumers.

The core material, paperboard, is a renewable resource derived from sustainably managed forests. More importantly, the vast majority of paper tubes are made from recycled paper. By using recycled content, we divert waste from landfills and reduce our reliance on virgin materials. This significantly lowers the environmental footprint of the packaging. Furthermore, paper tubes are fully recyclable. Unlike complex multi-layer plastics, a cardboard tube can be easily processed in most municipal recycling programs, allowing the paper fibers to be used again.

This focus on eco-friendly paper and recyclability makes tube packaging a responsible choice. Many tubes are also biodegradable, meaning they can break down naturally over time. By choosing environmentally friendly packaging like a paper tube, you are making a clear statement about your brand's values. It’s a tangible demonstration of your commitment to the planet, which can build trust and loyalty with your customers.

What Industries Benefit Most from Custom Paper Tube Packaging?

The versatility and premium feel of custom paper tube packaging make it a suitable choice for a wide array of products. However, some industries have particularly embraced this packaging style to elevate their brands and protect their goods. The unique form factor helps products stand out in both physical retail and e-commerce environments.

The cosmetic and beauty industry is perhaps the largest user of custom paper tubes. The elegant, sleek shape is a perfect match for luxury skincare, makeup, and personal care items. We produce a huge number of cosmetic tubes for products like serums, lotions, and powders. The sturdy construction also provides excellent protection for fragile glass bottles and jars. This makes cosmetic tube packaging a go-to for brands that need both beauty and brawn.

Here’s a list of industries where tube packaging thrives:

- Cosmetics & Personal Care: Ideal for lipstick tubes, serums, creams, and bath salts.

- Food & Beverage: Excellent for dry goods like tea, coffee, spices, and snacks. It's also a popular choice for food packaging for items like gourmet cookies or high-end spirits.

- Apparel & Accessories: Used for packaging rolled t-shirts, socks, ties, and other accessories to create a gift-like experience.

- Candles & Home Goods: A candle tube provides a stylish and protective home for fragile candles.

- Stationery & Art Supplies: Perfect for posters, prints, and even high-end pens. The classic wrapping paper tube is a form of this.

A Look Inside the High-Quality Paper Tube Manufacturing Process

Understanding how a high-quality paper tube is made gives you an appreciation for its strength and precision. The tube manufacturing process is a sophisticated operation that combines heavy machinery with meticulous quality control. It all starts with large rolls of paperboard, often brown kraft or white paper, which are slit into narrow ribbons.

These ribbons are fed into a spiral winder. As each ribbon is drawn onto a custom-sized steel mandrel, it is coated with a layer of adhesive. The machine winds the layers at a slight angle, one over the other, to form a continuous, rigid cardboard tube. The strength of the final paper tube is determined by the number of paper layers and the type of adhesive used. We can precisely control this to create everything from a lightweight lip balm tube to a super-strong industrial core.

Once the continuous tube is formed, it is cut to the exact required length by a series of sharp blades. From there, the customization process begins. The outer printed wrap is applied, and the ends are finished—either by rolling the edge for a smooth finish or by attaching separate end caps made of paper, metal, or plastic. This precise and controlled process ensures that every paper tube we produce is consistent, durable, and meets the highest quality standards.

What Are the Differences Between Mailing Tubes and Product Packaging Tubes?

While they may look similar, there's a significant difference between a standard mailing tube and a custom paper tube designed for retail product packaging. Understanding this distinction is key to choosing the right packaging for your needs.

Mailing tubes, also known as shipping tubes, are designed primarily for function over form. Their main purpose is to protect documents, posters, artwork, or other long items during transit. They are typically made from thick, durable kraft paper and feature plastic end caps that fit securely to keep the contents safe. While you can get custom mailing tubes with simple one-color printing, their main focus is on strength and durability to withstand the rigors of the postal system.

On the other hand, custom paper tubes for product packaging are designed with presentation as a top priority. While they are also very durable, every element is crafted to enhance the brand and the unboxing experience.

- Aesthetics: They feature high-quality, full-color printing and a wide range of special finishes.

- Construction: They often have sophisticated structures like telescoping lids or rolled edges for a seamless, premium feel.

- Materials: They use a variety of specialty papers and can incorporate elements like metal lids or ribbon pulls.

In short, a mailing tube is for shipping; a retail paper tube is for showcasing.

How Do You Choose the Right Paper Tube Manufacturer for Your Needs?

Selecting a partner to create your custom packaging is a critical decision. The right paper tube manufacturer will act as more than just a supplier; they will be an expert consultant who can guide you through the process, from design to delivery. A good partnership ensures your vision is brought to life flawlessly.

First, look for experience and expertise. An established packaging company with a long track record in tube packaging will have the technical knowledge to recommend the best materials, structures, and printing techniques for your product. Ask to see a portfolio of their work. At Yucai, our 15+ years as tube manufacturers have given us deep insight into what works for different products and markets, especially for cosmetic tube packaging.

Second, evaluate their capabilities and quality control. Do they offer custom sizes and a wide range of finishing options? What is their quality assurance process like? A reliable manufacturer will have strict controls in place to ensure consistency and quality across your entire order. Finally, consider communication and service. Your partner should be responsive, transparent, and easy to work with. For small or growing brands, flexibility on minimum order quantities (MOQs) is also crucial. We pride ourselves on offering no MOQ, making high-quality custom packaging accessible to businesses of all sizes.

What are Lip Balm Tubes and Other Small-Format Cosmetic Tubes?

Within the vast world of cosmetic packaging, small-format paper tubes have carved out a significant niche. Paper lip balm tubes are a perfect example of this trend. They are an eco-friendly and stylish alternative to the traditional plastic twist-up tubes. Made entirely from paperboard, they are often designed with a push-up bottom, making them a novel and sustainable choice for lip balm and solid perfumes.

This move towards eco-friendly cardboard applicators extends beyond just lip balm. We create small-diameter custom paper tubes for a variety of cosmetic products:

- Lipstick Tubes: A luxurious paperboard tube can replace plastic lipstick casings.

- Concealer Sticks: Paper tubes offer a unique and sustainable option for solid stick formulas.

- Solid Perfumes & Deodorants: Cardboard tubes are a popular choice for "zero-waste" or natural deodorant and perfume brands.

These paper lip balm tubes and other cosmetic tubes are not only better for the environment, but they also offer a unique tactile experience for the consumer. They align perfectly with the values of natural and organic beauty brands, allowing the packaging to reflect the purity of the product inside. It's a small change that can make a big statement about a brand's commitment to sustainability.

What Finishing Options Make Custom Paper Tubes Offer Endless Possibilities?

The final step in creating a truly exceptional custom paper tube is the application of special finishes. These are the details that take your packaging from simply functional to truly memorable. Finishing options for paper tubes add texture, shine, and a tactile quality that engages the senses and elevates the perceived value of your product. These are the touches that make your packaging stand out on a crowded shelf.

Here are some of the most popular finishes that can add a premium touch to your packaging:

- Lamination: A thin film applied over the printed paper. A gloss lamination creates a shiny, vibrant look, while a matte lamination provides a subtle, sophisticated, and smudge-resistant finish.

- Soft-Touch Coating: This special matte finish has a velvety, rose-petal texture that feels incredibly luxurious to the touch. It invites the customer to hold and interact with the packaging.

- Foil Stamping: Applying metallic foil (in gold, silver, copper, or a variety of colors) to specific areas of the design. This creates an eye-catching, high-end effect perfect for logos or accents.

- Spot UV: Applying a high-gloss varnish to specific "spots" on a matte background. This creates a striking contrast in texture and shine, making certain design elements pop. An excellent example is our Tube Box with Spot UV.

- Embossing & Debossing: Creating a raised (embossed) or recessed (debossed) 3D effect on the paper. This adds a sophisticated, tactile dimension to your packaging design.

By combining these techniques, the paper tubes offer endless possibilities for creating a unique and captivating packaging experience.

Key Takeaways to Remember

- Versatile by Design: Paper tube packaging is a strong, durable, and highly customizable solution suitable for a wide range of industries, especially cosmetics and food.

- A Sustainable Choice: Made from renewable and often recycled paper, cardboard tubes are a recyclable and eco-friendly packaging option that aligns with modern consumer values.

- Customization is Key: From size and structure to printing and premium finishes, you can customize every aspect of your paper tube to perfectly reflect your brand identity.

- Kraft is King for Natural Brands: Kraft paper tubes offer a rustic, organic aesthetic that instantly communicates a brand's commitment to natural ingredients and sustainability.

- Choose Your Partner Wisely: Work with an experienced paper tube manufacturer who can offer expert guidance, flexible MOQs, and a commitment to quality.

Post time: Nov-12-2025