Two Tuck End Box

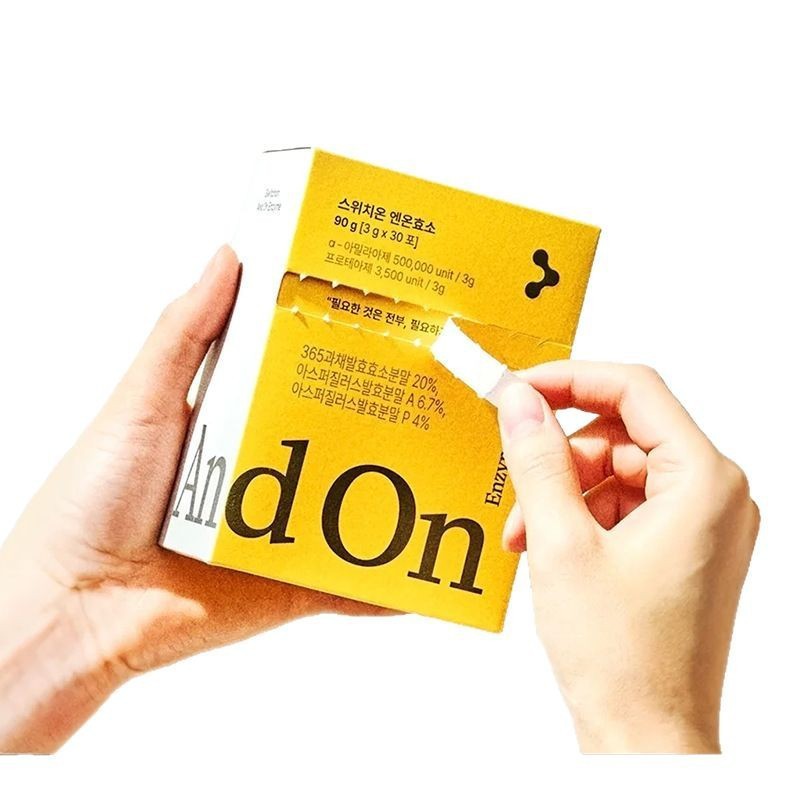

Two tuck end box

Two tuck end box is a common type of packaging box. Its feature is there are sockets on both the top and bottom of the box, and both ends can be opened. It can be either double-opening or single-opening. This kind of box is mainly used for packaging small and simple goods, such as phone cases, cosmetics and headphones, etc. The production process of two tuck end box is relatively simple. After die-cutting, they are pasted and then folded into shape, and the cost is relatively low.

Application

Due to its relatively simple production process (die-cutting followed by gluing and folding into shape) and low cost, it is often used to package small and simple items such as phone cases, cosmetics, headphones and toothpaste. These goods usually do not require overly complex packaging. Double insertion boxes can not only meet the need to protect the goods but also control costs.

How to enhance the texture of your box

Although the texture of tuck end boxes is usually relatively light and thin, and their overall quality may not be as good as that of other types of boxes, their appeal can be enhanced through improvements in design and materials. For instance, using higher-quality paper, enhancing the printing effect or applying special surface treatment techniques, etc., can all improve the overall texture of the double insert box.

| material choice | white cardboard, white kraft paper, brown kraft paper, texture paper |

| Crafts | Hot Stamping, Embossed, Debossed, Spot UV |

Difference between two tuck end box and lock bottom box

Two tuck end boxes and lock bottom boxes may look very similar in appearance, but their structures are different. The two tuck end box has sockets on both the top and bottom, making it suitable for packaging small and simple goods. The lock bottom box has a socket at the top and adopts a button-bottom structure at the bottom, which has a better load-bearing effect and is suitable for heavier products.